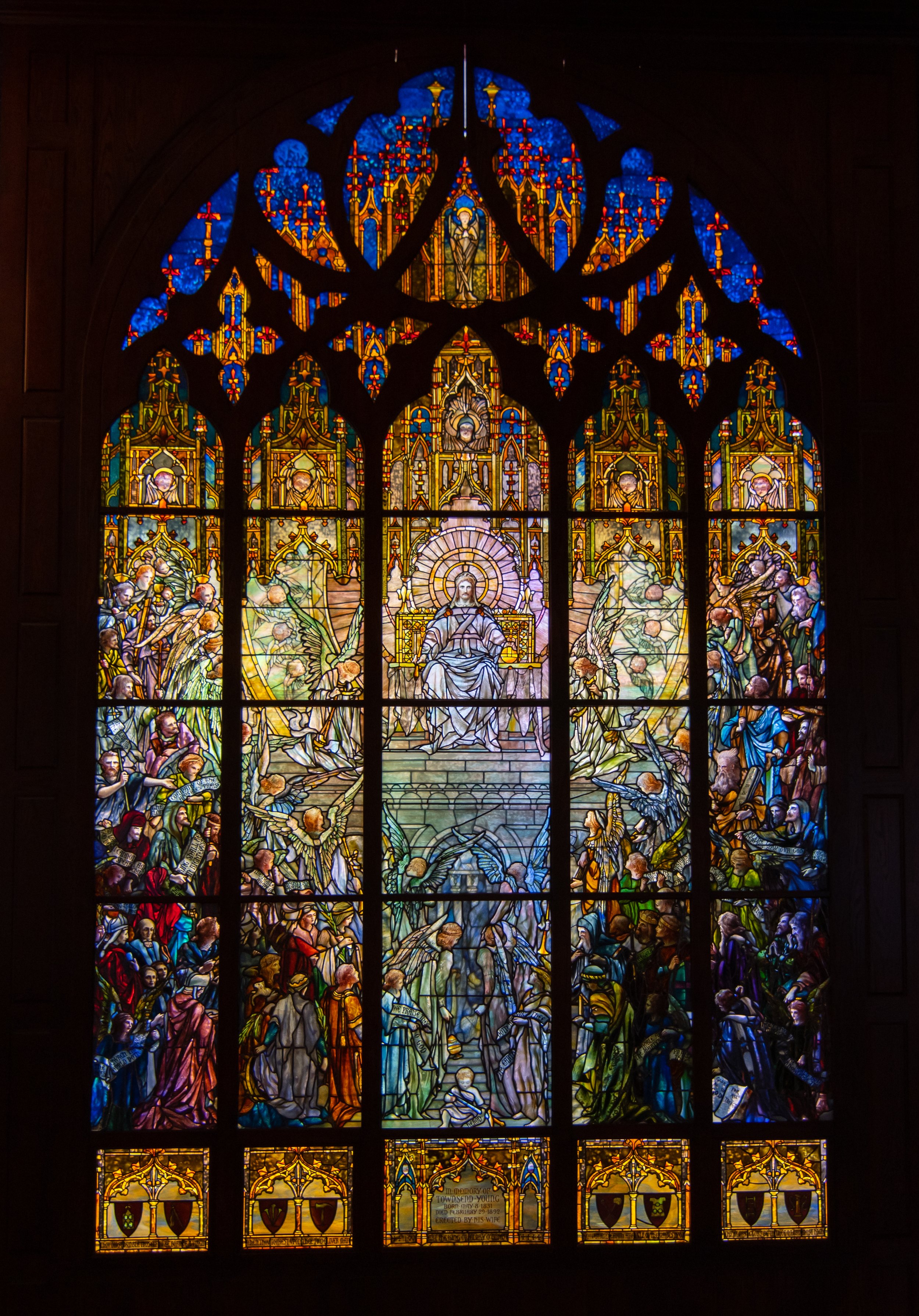

Tiffany Technique

Tiffany glass was created in a variety of ways. Some glass pieces were cast in molds while others were rolled out onto a flat surface and manipulated. To create the cloth-like drapery glass, artisans used hand tools to move and twist hot glass into folds. By mixing two or more colors of molten glass together, they were able to create streaky or striated glass. Confetti glass was made by pouring molten glass on top of pieces of colored glass or by sprinkling pieces of colored glass into hot glass.

The creation of a stained-glass window began with a small sketch that was followed by a cartoon, a full-scale painting of the proposed window. The cartoon was cut into templates to be used to produce the many individual glass-shapes and sizes required for the pattern. The glass for the window design was then chosen from the thousands of colors and textures that were stored and coded in sheets. Tiffany’s technique of plating required the use of multiple layers of glass that would allow him to achieve the color he wanted when the light would pass through. Once all the glass was selected and cut, the window was put together in one of two ways:

The leaded-glass technique was the traditional method of stained glass fabrication for centuries. It required artisans to fit the cut glass into flexible lead cames, which are strips of lead shaped like construction “I-beams.” The glass pieces are placed on either side of the “I” and soldered and mitered at the joints. Finally, the window is glazed with putty in order to solidify the overall panel. This method was used to hold big flat pieces of glass, but was not suitable for making curves. These lead cames were difficult to use for complex patterns requiring many small glass pieces.

The copper-foil technique was introduced as a way to better construct 3-dimensional works, such as lampshades and to accommodate tiny pieces of glass. For this technique, artisans wrapped the edges of glass pieces with a thin copper foil about 0.002 inch in thickness before they were laid out and soldered together. Unlike lead came, which is soldered only at points of intersection, the copper foil is soldered along the entire joint where it touches another piece of glass. This copper foil was treated with beeswax on one side and muriatic acid on the other. The beeswax permitted the foil to adhere to the glass, while the muriatic acid permitted solder to bond to the foil.

Chervenka, M. (n.d.). The copper foil technique. Real Or Repro. Retrieved April 21, 2022, from https://www.realorrepro.com/article/The-Copper-Foil-Technique

The Charles Hosmer Morse Museum of American Art. (2021). Secrets of Tiffany Glassmaking. Retrieved from https://www.morsemuseum.org/on-exhibit/secrets-of-tiffany-glassmaking

Jancik Arts International (2021). Musings About Stained Glass Techniques and Metal Art. Retrieved from https://jancikarts.com/the-copper-foil-vs-leaded-technique-myth/#:~:text=In%20the%20late%20nineteenth%20century,piece%2C%20then%20crimping%20and%20smoothing