- Westwood Aerogel

- Westwood Aerogel

Welcome to Westwood Aerogel, your gateway to the world of zero emissions and low costs aerogel. We are dedicated to revolutionizing sustainable technology and bringing you the latest advancements in aerogel insulation production…

Explore our website to discover how aerogel's exceptional thermal insulation properties can drive energy efficiency in various industries.

Join us in shaping a sustainable future powered by innovation and responsible production practices.

Aerogel

Applications

-

Revolutionizing aerospace with sustainable, low-cost aerogel for enhanced efficiency, reduced fuel consumption, and improved passenger comfort. Embrace the power of aerogel for a sustainable future in aerospace.

-

Transforming batteries with sustainable, low-cost aerogel for enhanced performance, longer life, and environmental responsibility. Embrace the power of aerogel for a sustainable future in battery technology.

-

Powering renewable energy with sustainable, low-cost aerogel for increased efficiency, enhanced energy storage, and a greener future. Embrace the power of aerogel for sustainable renewable energy solutions.

-

Revolutionizing building envelopes with sustainable, low-cost aerogel for superior insulation, energy efficiency, and environmental responsibility. Embrace the power of aerogel for a greener and more efficient building envelope.

Innovation

Hydrophobic Properties

Superior Insulation Flexible

Category Two

ZeroTherm: Ambiently Dried Aerogel Insulation

-

Batteries and electronics work best in a very narrow temperature range. Insulation maintains a constant temperature, even in weather conditions.

-

Improving the efficiency for battery storage or renewable energy sources extends the lifetime of operation.

-

Improving safety in battery technologies reduces overall warranty costs.

Double pane windows with Ar gas often leak and adsorb moisture between panes. Replacing the filler gas with ZeroTherm does not demonstrate these traditional failure modes.

-

Insulating glass units help to maintain a comfortable temperature in the room, which can be beneficial for people who are sensitive to temperature changes.

Insulating glass units can help to reduce noise pollution, which can be beneficial for people who live in busy or noisy areas.

-

ZeroTherm can help to reduce the environmental impact of buildings and can support LEED certification.

Estimated 98% reduced energy cost of production compared to leading insulation materials.

-

Government incentives, such as tax credits or rebates, can be a driver for consumers to install energy-efficient technologies.

-

Maintain a single temperature for battery and other renewable applications to maximize operational efficiency.

ZeroTherm offers significant energy savings and can help to reduce heating and cooling costs, which is a major concern for many consumers.

Our Process

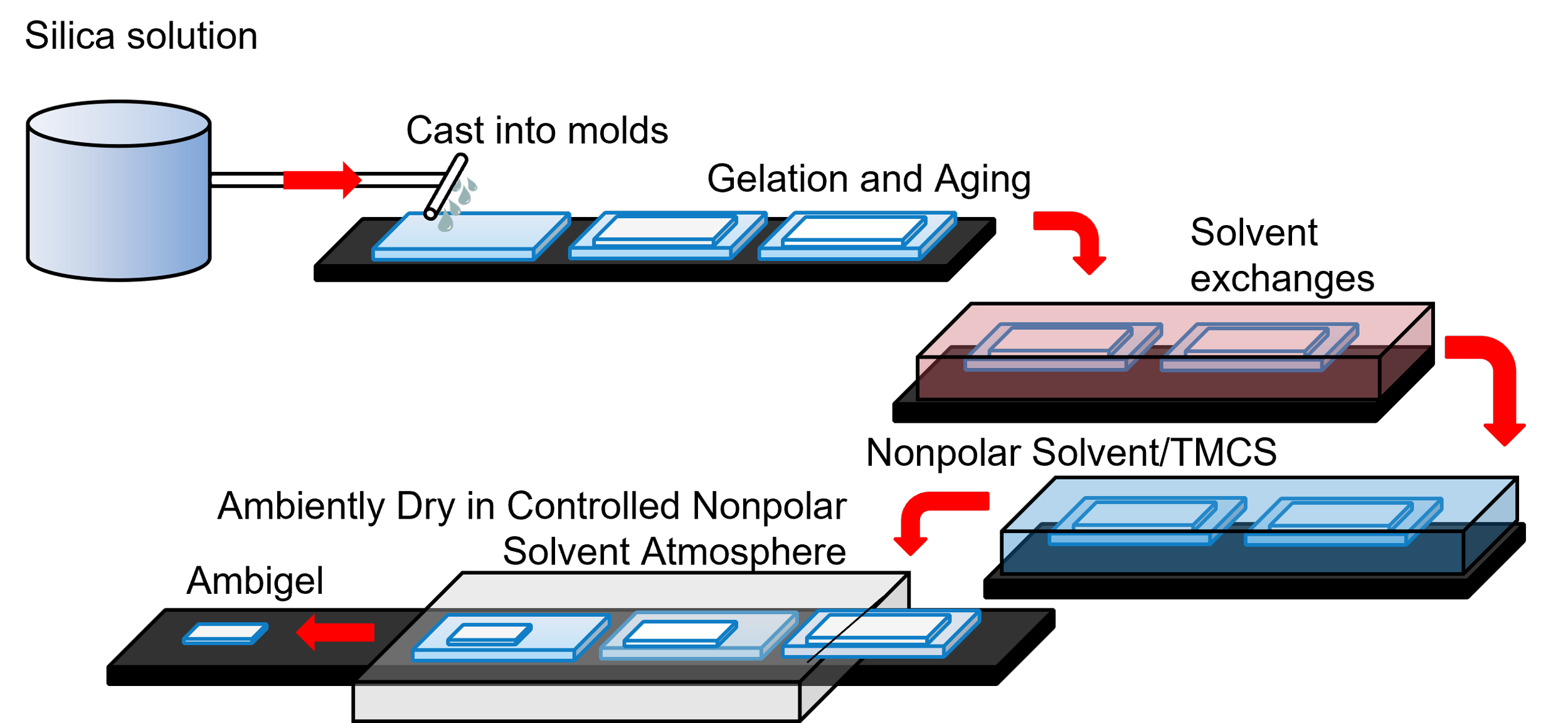

By incorporating an ambient drying process, you can shift to a continuous line model from start to finish, mirroring the float-glass process for a low temperature setting. The float-glass model involves flowing molten glass on a nonstick substrate followed by cooling in a controlled environment. This has proven scalability as it is the current model for glass manufactures across the nation. Similarly, we will cast the gels on a nonstick substrate, bring it continuously though solvent exchange to the desired drying liquid, and transition into a strictly controlled drying atmosphere via conveyor belt, which is a truly continuous process. Our advanced manufacturing process can make aerospace grade aerogel materials at an estimated 98% energy reduction from traditional manufacturing.

U.S. Patent No. US20210207428A1

Emerging

from the lab

Our mission is to take ZeroTherm out of the academic setting, and spearhead it’s development into a sustainable energy product. Historically, there is a disconnect between what we develop as researchers, and what makes it into industry. At Westwood Aerogel, we aim to bridge that gap for our ambiently dried aerogel technology, which will have global implications for green technologies and sustainability.

*Estimated Embodied Carbon Footprint (CO2)

Meet the Inventor

Dr. Patricia McNeil

Founder, CEO

Dr. Patricia McNeil comes from Professor Bruce Dunn’s Group in the Department of Materials Science and Engineering at UCLA. She obtained her PhD in Materials Science and Engineering at UCLA in 2023 and interned at Nippon Sheet Glass in 2020. As a graduate student she was part of the Innovation at the Nexus of Food, Energy, and Water Traineeship, where she obtained a Leaders in Sustainability Certification. Currently she researches utilizing sol-gel chemistry to develop ambiently dried aerogel materials for thermal insulation. From this work, she is founding Westwood Aerogel, and has been invited to submit a Phase 1 NSF SEED Fund Proposal.

Meet the Team

-

Daniel Farzannekou

CO-FOUNDER/COO

-

Dr. Bruce Dunn

TECHNICAL ADVISOR

-

DC Palter

INDUSTRY ADVISOR

-

Simon Yegikyan

SOFTWARE ENGINEERING INTERN

Request a Sample

Contact us for further inquiries